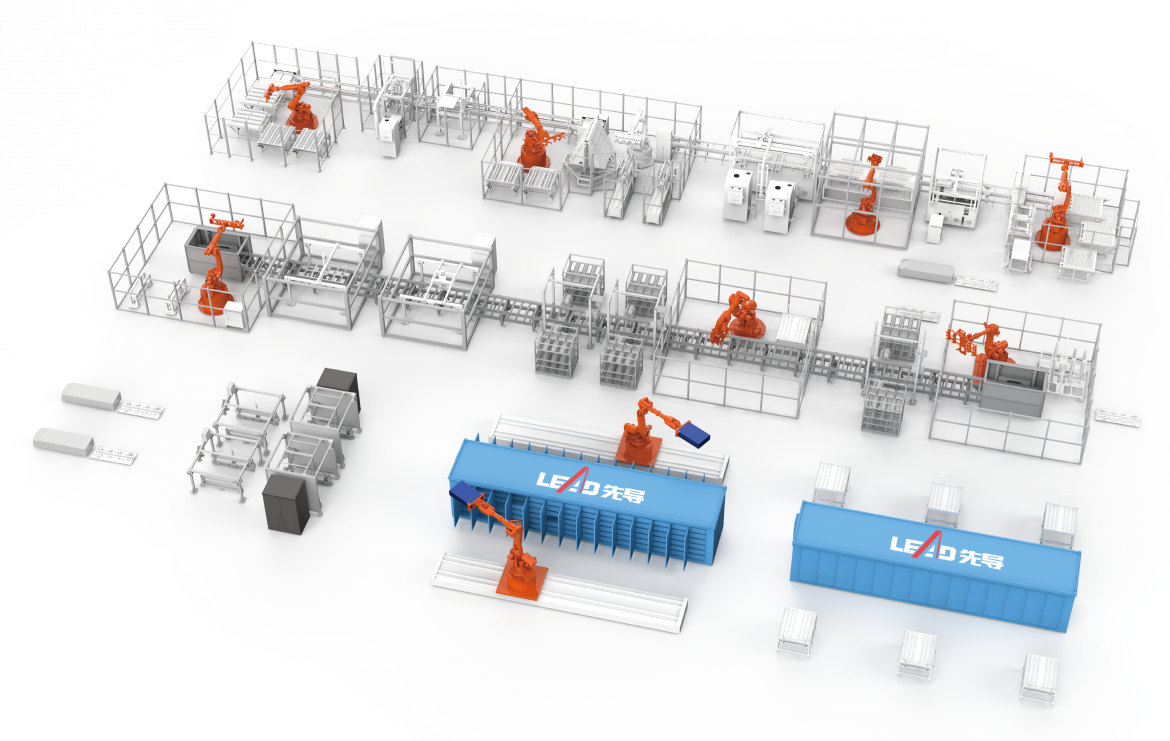

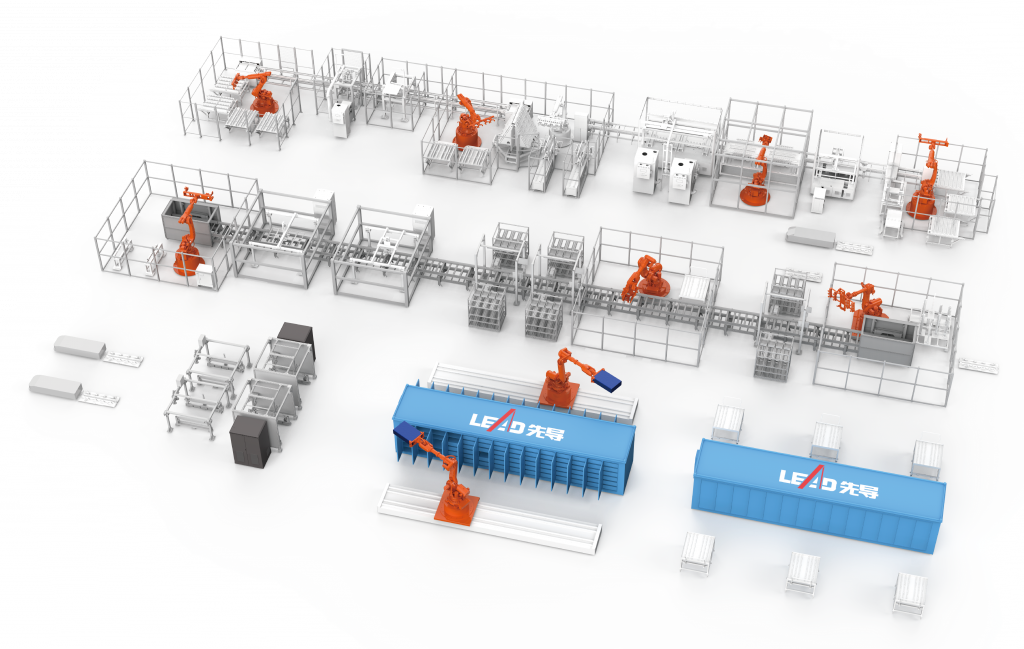

Module to pack battery production plays a crucial role in enhancing the performance and efficiency of energy storage solutions. LEAD Intelligent is at the forefront of this transformation, offering advanced systems that maximize automation and efficiency across the production process. By leveraging cutting-edge technology, LEAD Intelligent enables manufacturers to produce batteries faster, more reliably, and at a higher quality.

Maximizing Automation in Module to Pack Battery Production

The module to pack battery production process requires a high level of precision and speed. LEAD intelligent achieves this through its fully automated production lines, with an automation rate reaching 95%. This allows for consistent quality, reduced human error, and faster throughput. With a production efficiency rate of up to 15PPM (products per minute), manufacturers can meet the high demands of the battery market while maintaining stringent quality standards.

Flexibility with Quick Changeover Capabilities

LEAD Intelligent’s module to pack battery production system is designed to provide flexibility, making it easy to switch between different products. This capability allows manufacturers to quickly adapt to changing production needs without disrupting overall efficiency. Quick changeover supports a diverse range of battery models, enhancing the system’s versatility and ensuring manufacturers can meet various market requirements with minimal downtime.

Enhancing Whole-Line Efficiency

By automating every stage of the module to pack battery production process, LEAD Intelligent significantly enhances whole-line efficiency. The system’s ability to maintain high-speed production at 15PPM while ensuring the highest product quality leads to reduced operational costs and optimized production timelines. This efficiency not only accelerates manufacturing but also improves profitability by lowering energy consumption and minimizing waste.

Conclusion

LEAD Intelligent continues to drive innovation in module to pack battery production, setting new standards for automation, flexibility, and efficiency in the battery manufacturing industry.