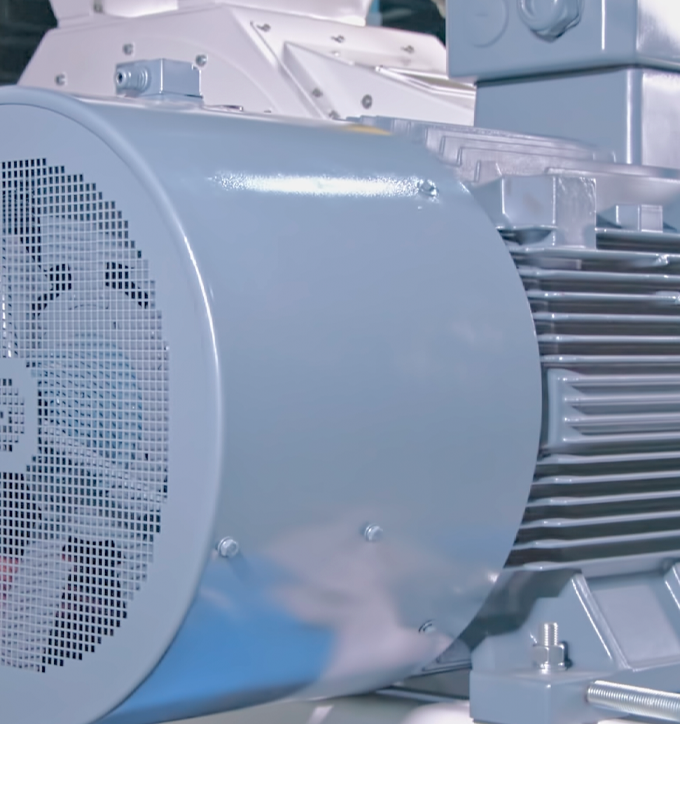

Precision engineering meets operational excellence in modern feed processing. FAMSUN, a global innovator in feed and food engineering machinery, delivers the KX Series Aquafeed Pellet Mill – a feed mill pellet machine engineered to revolutionize safety standards and production efficiency. This advanced system ensures optimal nutritional integrity while addressing core operational challenges in aquafeed manufacturing.

Engineered Safety: Compliance and Automation

Operating a feed mill pellet machine demands uncompromising safety protocols. The FAMSUN KX Series meets rigorous CE safety standards, integrating critical safeguards throughout its design. Automated features like the centralized lubrication system minimize manual intervention, reducing contamination risks and maintenance hazards. The electric ring die lifting mechanism eliminates strenuous manual handling, enhancing operator safety during die changes. This proactive approach to safety makes FAMSUN’s feed mill pellet machine a responsible choice for modern facilities prioritizing workforce protection and compliance.

Precision Efficiency: Smart Controls & Reduced Downtime

Maximizing uptime is critical in high-volume feed production. FAMSUN’s feed mill pellet machine incorporates intelligent efficiency solutions. The angle-adjustable cutter, accessible via a split-door structure, enables swift micro-adjustments for perfect pellet length consistency without halting production. Automated lubrication extends bearing life and prevents unscheduled stops, while the electric ring die system cuts changeover time significantly. These innovations collectively elevate throughput, reduce energy-per-ton costs, and ensure continuous operation – transforming your feed mill pellet machine into a productivity powerhouse.

Optimized Performance for Demanding Formulations

Aquafeed’s high-fat, high-moisture recipes challenge conventional equipment. The KX Series feed mill pellet machine conquers these demands with specialized engineering. Robust construction handles abrasive ingredients, while precision temperature control maintains starch gelatinization for optimal water stability. The synergy of FAMSUN’s cutter precision and die design ensures uniform pellet density, reducing fines by up to 15% versus standard mills. This technical refinement delivers measurable gains: higher feed conversion ratios, reduced waste, and consistent quality – proving why advanced feed mill pellet machine technology is highly valuable for competitive aquafeed producers.

Conclusion

Beyond machinery, FAMSUN provides integrated solutions where safety protocols, energy efficiency, and precision manufacturing converge. The KX Series exemplifies how innovative feed mill pellet machine design elevates operational standards while safeguarding your workforce and output quality. Experience measurable ROI through reduced downtime, lower operating costs, and superior pellet performance.